NIJ STANDARD 0101.06 FOR BULLETPROOF ARMOR

Most of the bulletproof armor when tested met the standard. However, when they are worn by an officer in a hot and humid environment for actual duty (e.g. a physical confrontation) for several hours a day, several days a week/month/year , the armor’s performance can be greatly reduced.

So how do we know if a bulletproof armor is good enough to keep us on task for a long time?

To ensure bulletproof armor is effective in protecting security personnel and police officers, the National Institute of Justice (NIJ) has established a standard for bulletproof armor and a It was first tested in 1972. After 5 updates, the current latest standard is NIJ 0101.06 which is the most comprehensive, rigorous and safe standard for users.

A set of bulletproof armor tested and certified to NIJ 0101.06 increases user safety in three ways:

- By increasing performance against the most advanced weapons.

- By improving reliability.

- By its outstanding durability, it ensures that the user can cope with the danger of frequent wear and for a long time.

Changes to the testing and requirements of this standard have been introduced for the following reasons:

- To improve performance so that users receive the most effective protection.-

- To ensure the armor will work in real-world applications, not just on paper, throughout the life of the product.

Higher speed:

- Test velocities increased for armor types IIA, II and IIIA.

- The test velocity is set for testing under different conditions.

- Test rounds with special threat and high velocity.

Shooting position:

Previously, in testing, bullets were fired spread across the board according to the NIJ 0101.04 standard. But for the NIJ 0101.06 standard, the 3rd, 4th and 6th bullets must be fired into a 3.94 inch circle. This will ensure that the bulletproof vest can withstand multiple bullet impacts in the same area while still ensuring a PFS of less than 44mm.

Dimensions of bullets tested against bullets:

Warheads tested in accordance with NIJ 0101.06 should be of the following sizes: smallest, small, medium, large and largest.

Bulletproof vests also need to be tested under specific conditions, including being dropped into a water tank of approximately 21 degrees for 30 minutes. The previous NIJ 0101.04 standard only required a 6-minute water spray test, which makes the armor not necessarily water resistant.

In addition, the test samples also need to be rotated 72000 revolutions in 10 days. The required temperature is 65 degrees Celsius, with 80% humidity before the ballistic drag test.

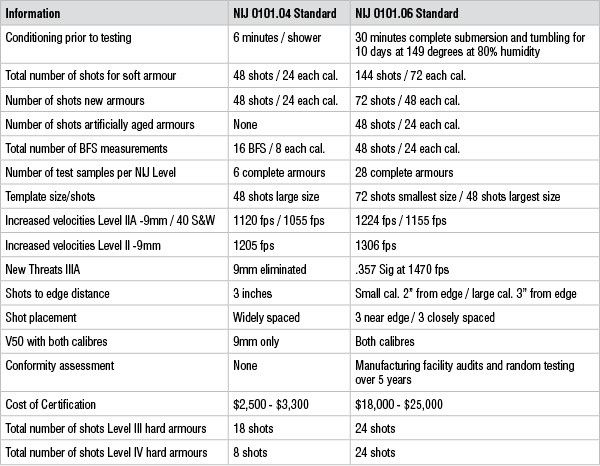

The following table shows more specifically the evaluation and testing criteria of the NIJ 0101.06 standard (with comparison with the old NIJ 0101.04 standard):

The NIJ 0101.06 standard is more focused on safety and everyday use than the previous NIJ 0101.04 standard. This also ensures that standard bulletproof armor will always do its job well.

Hopefully this article will help you gain a little more knowledge about bulletproof armor evaluation standards and help you choose the right products for your mission and unit.